Every organization that involves the operation of systems or equipment needs a document that provides detailed information on how to troubleshoot, maintain, and operate this equipment properly. This can be vital in reducing downtime and ensuring that the organization meets relevant safety and quality standards.

This is where an O&M manual comes in. This article contains everything you need to know about the importance of an operating and maintenance manual, the various types, the relevant information that should be included when you create a maintenance manual, and a step-by-step process for creating one that will be valuable to your personnel.

Whether you’re creating a small or large business, this guide has all the information you need to create a comprehensive manual that will boost the effectiveness of your organization’s operations.

What is a maintenance manual?

A maintenance manual refers to a document that contains all the necessary details on the upkeep of equipment and property. The operating and maintenance manual contains information that serves as detailed guidance for maintenance personnel on keeping workers safe, minimizing the chances of unplanned shutdowns, extending the life cycles of assets, and reducing maintenance costs.

Therefore, the target audience for the O&M manuals is usually third-party contractors, maintenance technicians, and organizational managers. Any organization that wants to optimize asset management needs an O&M manual. This is because this manual contains outlines on how to complete tasks related to inventory management, safety inspections, proactive and reactive maintenance, and others.

Larger organizations will rely more on an operating and maintenance manual, as this helps ensure consistency in various facets of the company. However, this doesn’t mean that smaller organizations can’t benefit from this manual as they work on growing their operations. The huge advantage of starting early is that you won’t be investing so much time upfront.

It is even more critical for medium and large companies to have an operations manual because there are lots of processes and people involved. Without a manual, there will be a lot of time and energy spent in training new employees as they are assigned new tasks, and this increases the risk of losing the consistency of work. Also, without properly documented procedures, there’s a higher risk of injuries, accidents, and errors in the workplace, which can cost the company a lot of money.

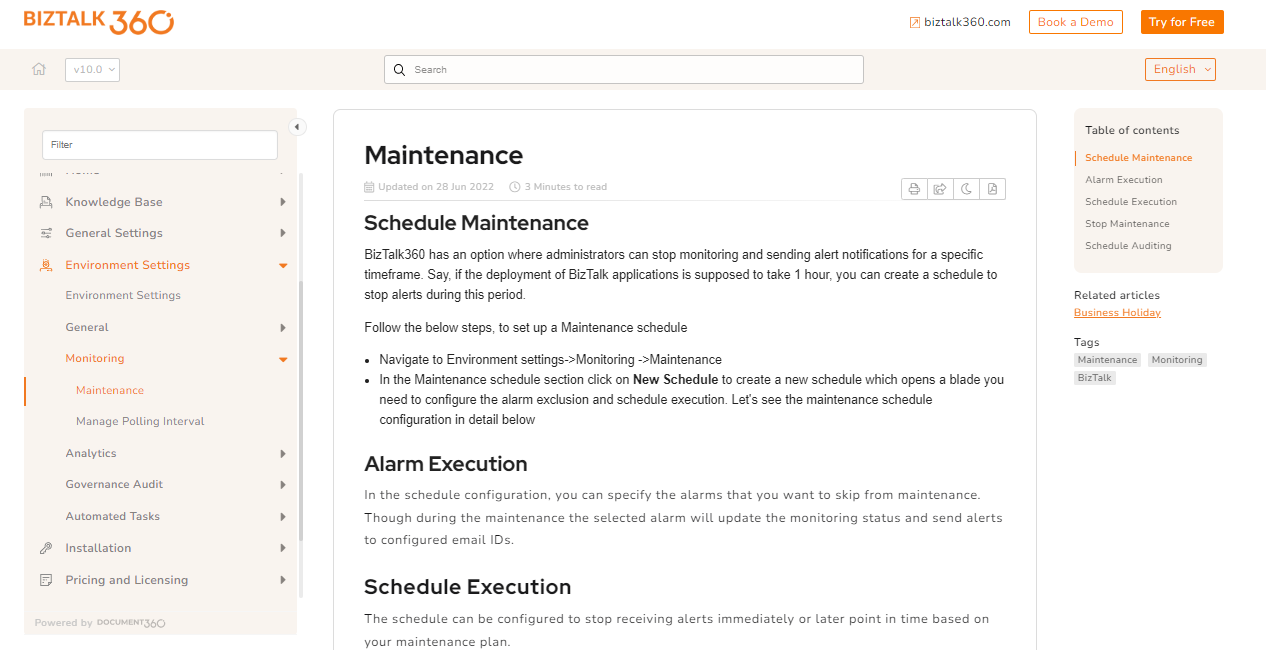

Maintenance Manual Example

Types of Operation and Maintenance Manuals

It’s better to separate the information based on the purpose. Create a detailed manual for each organization’s activity, function, and department.

-

- Manuals for product installation and maintenance: This manual contains details on installing and maintaining various products and assets within a facility.

- Backup and recovery protocols: When there’s a shutdown and a need to get things back on track as fast as possible, the backup and recovery protocols manual is a perfect tool.

- Manuals for information and software administration: You can’t rule out the importance of information and software administration in the organization as this manual serves as a source of guidance through this process.

- Human resources manuals: Human resources is an important aspect of every organization. This manual guides interaction between employees and management, and ensures that everyone knows what to do in every unique situation.

- Manuals for customer care support: This manual guides interaction with customers and how to answer their inquiries or solve issues satisfactorily.

- Procurement, Manufacturers, and Suppliers user guides: This manual is targeted at providing updated information on procuring assets, and interactions with suppliers and manufacturers of various equipment.

- Emergency and safety user guide: You can’t rule out the chances of emergency situations within the facility. However, this safety user guide contains instructions on the protocol to take in the event of an emergency.

- Industrial aid manuals: An industrial setting is a home to lots of heavy machinery that requires handling by experts. Industrial aid manuals provide the right level of guidance for handling this equipment, including details on maintenance and repairs.

- Quick reference manuals: This manual usually contains up-to-date outlines for quick references on everything employees need to know about the facility.

Also Read: How To Create a Software Installation Guide For Your Customer

Components of an operation and maintenance manual

You might wonder what components you should include while creating an operation and maintenance manual. Here are the components that you have to include in your manual.

Overview of Company Background

This refers to valuable information about the company that represents a general overview of the physical plant that’s the subject of the manual. This information includes personnel data, organizational charts, company history, and various other background info.

Machine Operating procedures

The machine operating procedures involve information on both proactive and reactive maintenance programs that help make sure that all important company assets are in great working condition. Reactive maintenance, also known as corrective maintenance, refers to the process of restoring relevant company assets after unexpected downtime. You can also refer to this as “unplanned software maintenance.” The machine operating procedures summarize scheduling protocols, troubleshooting processes, and more.

Equipment Specification information

These are specific, detailed information on the equipment and facility, including the types of building materials, floor plans, building specification information, site surveys, and other necessary information to be provided by both contractors and subcontractors.

Machinery Engineering Drawing

The machinery engineering drawing is detailed technical documentation that details the construction and design of various pieces of equipment used in the facility. They include specific information used in the construction of the equipment, including the materials, specifications, and dimensions. This drawing also provides information on the necessary safety requirements. With this, every employee will have handy information on troubleshooting, repair, and effective maintenance of any equipment within the facility. The machinery engineering drawings can also serve as a reference when there’s a need for replacement parts or to design new equipment to be compatible with the existing ones.

Equipment placement plans and maps

The information on equipment placement plans and maps involves a detailed layout of the location of all equipment within the facility. These include information on the location of access points, emergency shut-off valves, utility connections, and major pieces of equipment. The purpose of this is to ensure that all personnel in the facility can easily locate any equipment for regular maintenance tasks or in the event of an emergency.

It also helps in improving the overall efficiency of repair and maintenance operations, as it will be easier to identify potential hazards before they become a bigger issue. This can also be necessary to plan for future renovations, as they help facilities operate optimally.

SOP for Maintenance schedule

The standard operating procedure (SOP) for the maintenance schedule in the manual is needed for the clear and consistent instructions necessary to perform regular maintenance checks on assets. Therefore, this SOP documentation is an outline of the specific tasks to be handled, how often they should be done, and the procedures for doing them safely. This will ensure that regular maintenance checks are done periodically to keep all assets in optimal working condition.

Emergency protocols and safety guidelines

The emergency protocols and safety guidelines are a list of the necessary steps to take during emergencies, especially how to handle crisis communication and the right people and agencies to inform about the situation.

Documenting, storing, and sharing maintenance manuals made easy

Book A Demo

Benefits of Operations and Maintenance Manual

The operations and maintenance manual establishes a consistent manner to carry out provided processes in order to reach the intended result. While offering detailed processes to employees will enhance employee performance; it will go a long way toward developing a routine reliability, quality control, and stakeholder safety culture.

Every operational manager, regardless of organizational size or type, should put in place Operations and Maintenance manuals to obtain the following benefits:

Reduce downtime

Creating a maintenance manual that contains detailed information on the best practices for operating and maintaining equipment within a facility, is one of the best ways to reduce downtime. This is because the manual would contain sufficient information and instructions on how to troubleshoot and repair faulty equipment. Therefore, this will reduce the chances of confusion when there is a set guideline for solving the problem effectively.

The maintenance manual also contains information for periodic maintenance schedules, which ensures that personnel can detect errors earlier, leading to prompt solutions that can prevent total shutdown while prolonging the lifespan of assets. Quick access to vital information ensures that personnel can identify and fix errors promptly and effectively, reducing downtime.

Helps to maintain safety standards

With detailed information on how to operate and maintain equipment, personnel will be properly equipped with the tools they need to maintain safety standards within the premises. Usually, the O&M manual contains information on safety procedures and precautions to take when working with diverse equipment. This also includes typical hazards and warnings to minimize the chances of errors.

Therefore, with clear instructions for equipment handling, troubleshooting, and routine maintenance, the chances of injuries and accidents within the facility can be kept to a minimum. This is because personnel can easily identify and correct potential threats to safety before they become a huge problem. The maintenance manual should also contain emergency procedures that reduce the risk of damage, as everyone is fully aware of what safety protocols to follow at the time.

Setting clear quality standards

Thanks to the detailed information in the maintenance manual on how to operate and maintain equipment properly, this is great for setting clear quality standards that help all equipment last longer with optimal performance. Usually, the information on troubleshooting, when to carry out maintenance checks, specifications on the materials and components of the equipment, and other best practices work together to make identifying problems easy. With this, employees don’t have to wait for a total breakdown of equipment before swinging into action for repair. With maintenance checks, they can detect errors early and nip the problem in the bud.

Accelerate learning and onboarding of new hires

The O&M manual has everything that new hires need to settle into the facility with ample knowledge of how to handle operations. This is a clear and comprehensive guide on maintaining and operating equipment, including vital information on operating principles, functions, and features of the equipment.

This will make learning faster as it helps new hires understand all equipment and their capabilities in a simple format. The information on routine maintenance and troubleshooting also helps the process of onboarding new hires become smoother, as there is little need for additional training. An up-to-date maintenance manual is a clear and concise reference that can help new hires become productive team members faster than ever.

How to Create an Operation and Maintenance Manual

It is crucial to create the manual in such a way that it impacts the organization’s efficiency in the long run. We’ve highlighted the steps you may take to establish and maintain an effective O&M manual.

1. Create a Plan

To create a maintenance manual, you need sufficient information that will make it valuable to your organization. Therefore, this won’t be possible without an adequate plan well in advance. So, start by creating an outline that details the stakeholders that are essential to this process. Clearly define the purpose of this O&M manual and the target audience. These are all important aspects of your plan that will ensure that you know who the contents are directed at and what they should contain.

2. Conduct Primary research

Information is an important aspect of every organization. Its importance is also emphasized when creating a maintenance manual. Your primary research should involve detailed information on the daily routines of the operators and technicians to ensure that all procedures and best practices are updated in line with what’s available at the facility. Be sure to interview the engineers, operators, and technicians directly to get first-hand information that will guide operations and be passed along to other personnel as the facility grows.

3. Assemble a team (define workflow)

The operations and maintenance manual shouldn’t be written by you alone. A team will help you work faster and identify gaps that you would otherwise overlook if you worked alone. So be sure to put together a team of experts, including managers, suppliers, and service engineers. These professionals will offer valuable input and define the workflow properly. This will encourage operators and technicians to use the manual, as it won’t seem like a book of rules from top management. Assembling a team is a great way to save time, as they will spot errors and inefficiencies that you can work together to tackle.

Also Read: How to Create Document and Workflow for Business Process

4. Choosing the software

As shocking as it may sound, a huge percentage of facilities still rely on paper records in the 21st century. This has numerous disadvantages that would be too long for us to cover, but here is a summary. One of the biggest reasons why paper records should be discarded is that printed manuals are difficult to update with new information. However, with the right software, managers can easily pull up the information, edit it, and redistribute it online without hassles. This is the best way to streamline the process.

Schedule a demo with one of our experts to take a deeper dive into Document360

Book A Demo

5. Design a template

The goal of the manual is defeated if more than half of the personnel within the facility are unable to read and understand the operations and maintenance manual. Therefore, you have to pay attention to how easy it is to scan the manual and how long it takes for employees to locate the sections they need within the document. With a consistent layout, there’s little chance of confusion, and that makes the manual more valuable to your target audience.

6. Create and review content

Now that you have the template designed and ready for use, the next step is to fill it with relevant content. These are the contents we outlined earlier in this article and the products of your primary data research. As soon as it’s completed, you should present it to relevant stakeholders for a detailed review. This will ensure that all information is up-to-date and valuable for its purpose.

7. Make it accessible

How can you ensure that every employee in the workplace can easily access your operating and maintenance manuals without jumping through hoops? If you follow our advice to use software, this will be easy. All you have to do is share it online or save the manual in a central folder that can be accessed by any employee within the facility.

8. Collect feedback

Feedback is the lifeblood of most businesses. For companies looking to turn a profit, the input of their target audience helps them ensure that they are satisfied with their products and services. This also applies to your facility. As your business grows and acquires new assets, your manual will need periodic updates. Therefore, this review process can’t be successful without the feedback of your employees. Since they are the ones who work closely with equipment within the facility, they will be in the best position to provide ample feedback on what works and suggestions for improving the manual.

9. Regularly update the manual

Designing and creating a single O&M manual shouldn’t be all there is to this process. As the company grows, there will be a need to input new and updated information. The last thing you want is a manual that contains redundant information on equipment, as this could put your personnel at risk. Since this will also contain safety guidelines, you need to periodically check that these safety practices still apply within your facility. As you also acquire new assets within the facility, you should include sufficient information on them in the manual.

O&M manual templates and examples

Here are our operating and maintenance manual examples that show a few scenarios where an O&M manual can come in handy:

-

- Fire protection systems: This includes all the information necessary to operate and maintain fire protection systems, including emergency and troubleshooting processes.

- HVAC systems

- Renewable systems

- Industrial machinery

- Plumbing systems

- Electrical systems

- Building automation systems: Apart from valuable information about maintaining and operating the equipment, the operations and maintenance manual for building automation systems also contains instructions for integrating with other systems and the steps to perform routine maintenance.

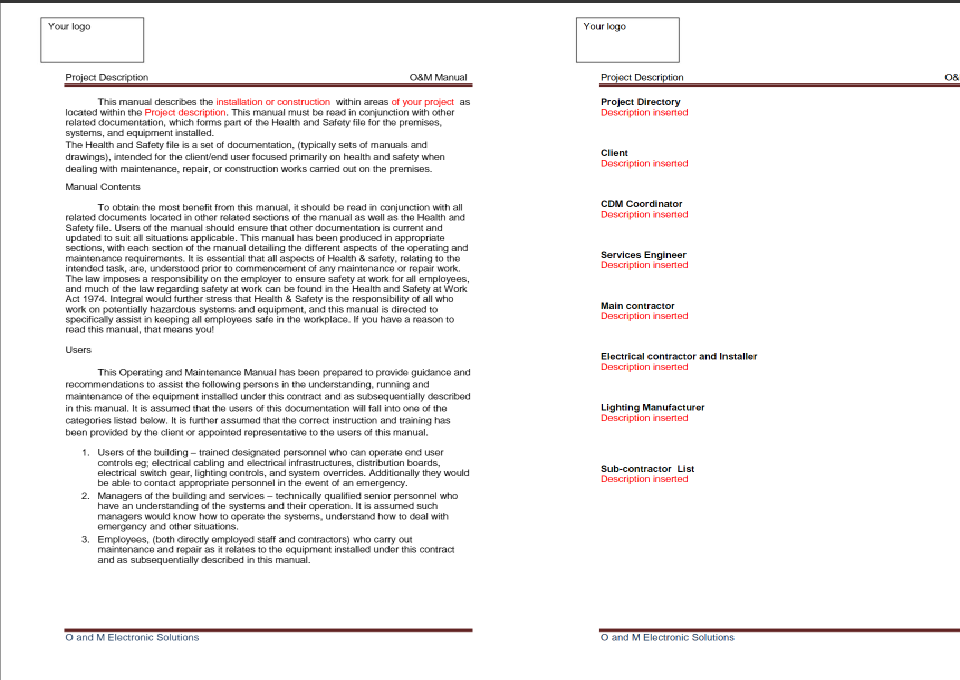

You don’t always have to design procedure manuals from scratch. While it may be necessary to have a bit of creative input for the sake of providing a maintenance manual tailored to your organization, using templates can make this even easier.

With templates, you have a visual representation of the important sections in your manual based on your industry, and you can tweak this to include relevant information that will be helpful to personnel within the facility.

Here is the operating and maintenance manual templates that will be very useful for you.

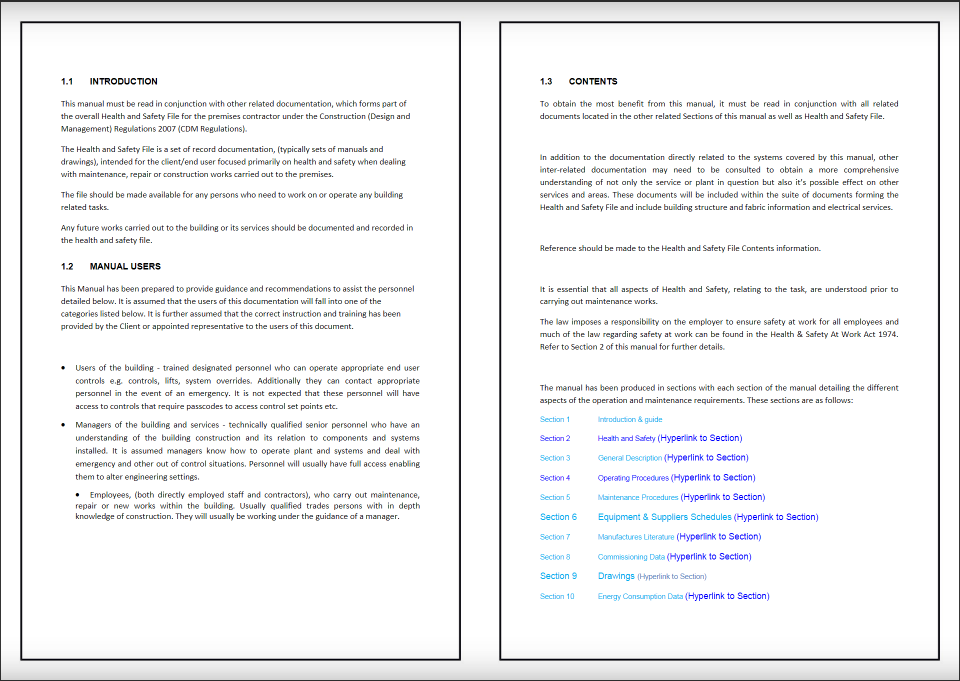

Plant operating manual template

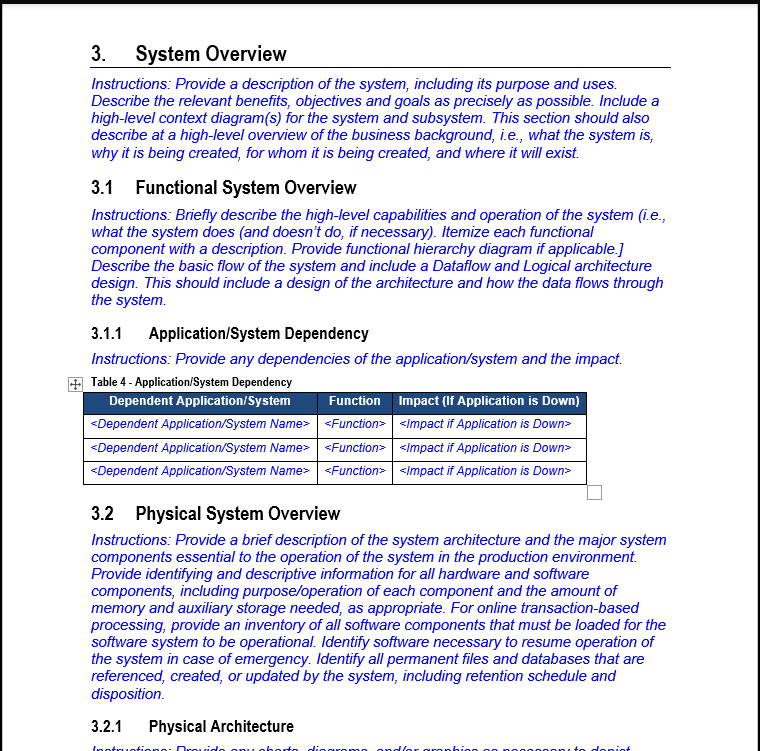

System Operation Manual Template

Conclusion

Having an operation and maintenance manual could just be the difference between a facility that works with little to no glitches and one that is prone to dangerous situations.

Therefore, this maintenance manual can serve as a valuable resource for your maintenance team, especially when put together with all relevant details using communication methods that are accepted all around.

An intuitive SOP software to easily add your content and integrate it with any application. Give Document360 a try!

GET STARTED