In manufacturing, every second matters. You are a new hire, your first week at work seems confusing and you are still awaiting instructions and training from your managers. Sound familiar? It happens more often than you think! And you’re also falling behind schedule. What’s the cause? Often, it boils down to misunderstood directions—or a complete lack thereof.

Many factories suffer from vague work instructions, resulting in expensive errors. These mistakes squander resources and leave workers feeling annoyed. Another common scenario is a new hire struggling to understand their role. Even experienced staff skip key steps due to unclear guidelines, leaving supervisors scratching their heads about what went wrong.

But there’s a solution! Well-designed manufacturing work instructions (MWIs) can fix this. MWIs break down complex tasks into clear, simple steps, ensuring everyone is on the same page.

In this guide, we’ll show you how to create effective MWIs. Say goodbye to confusion!

What Are the Benefits of Manufacturing Work Instructions?

Creating manufacturing work instructions may seem like an extra task, but the payoff is huge. Here’s how they benefit your operations:

Reducing Production Errors

Establishing Standard Operating Procedures (SOPs) in manufacturing work instructions is important. Fewer mistakes mean smoother operations and less guesswork. When staff have clear directions, they make fewer expensive mistakes. Picture a factory where all workers are in sync. Production lines operate without hiccups, and product quality improves.

A small slip in assembly can cause faulty products. Standard manufacturing work instructions help employees understand how to do their tasks correctly. They follow clear steps, reducing the chances of mixing up parts or skipping critical processes.

‘Less error = Less rework,’ decreasing time, materials, and money.

For instance, in an automotive plant, detailed work instructions help workers assemble components correctly. In the end, fewer faults mean fewer problems, better-satisfied clients, and improved revenues.

Assures Consistent Product Quality

One vital aspect of manufacturing is that the products must be of the same standard. Work instructions and user manuals provide essential guidelines that ensure your team performs each job simultaneously, reducing mistakes and variations.

Every product must meet the same high standards. With precise instructions, each batch remains uniform. In food manufacturing, for instance, the steps taken help to make all the snacks produced have the same taste and texture. This means that customers expect to get the same value each time they come to do business, building customer loyalty.

This, in turn, translates to happy customers and fewer complaints, which results in reduced expenditure while at the same time building a good reputation. In industries like pharmaceuticals, precise instructions are critical. A small deviation may lead to spoilage of the batch or, worse, harm to the consumers.

It creates a culture of quality when everyone follows the same process; hence, the employees have pride in what they produce.

Clear Communication Across Teams

Clear instructions ensure the coordination of engineers, technicians, and quality control teams. Writing and following standard work instructions allows everyone to be understood on the same platform, which in turn helps to overcome misunderstanding and confusion.

Clarity makes it possible for each department, including design, production, and quality assurance, to work as a team. Every team member knows their schedule and duties, which has the added advantage of increasing responsibility.

Whenever processes evolve, new procedures ensure that everyone gets up to speed when conducting their tasks. This minimizes disruptions and keeps the workflow steady.

Better Employee Training and Onboarding

Starting a new job can be confusing. Many employees feel lost without clear directions. This is where manufacturing work instructions come into play. They reduce training and enhance the onboarding process.

By having clear work instructions, the new employees will fully understand what is expected of them. It’s like having a roadmap. Rather than roaming around, they can concentrate on their work. This speeds up training.

Even the experienced worker benefits. Even the best employees do not mind having something to refer to. It reduces mistakes and increases efficiency.

It is convenient if the worker forgets something; they can easily refer to the instructions instead of looking around for assistance. This reduces downtime and keeps production going.

Manufacturing work instructions ensure that there is teamwork. It is relatively easy for the employees to share knowledge with one another. It enhances confidence in job delivery among the workforce and increases productivity at the company.

What’s the Process for Creating Work Instructions in Manufacturing?

Step 1: Crafting a Clear Title for Each Procedure

The title should let the worker know the task as soon as they read it. For example, instead of “Assembly,” write “Assembling the Hydraulic Pump Unit.” A clear title saves time and ensures workers find the right procedure quickly, especially in a busy manufacturing environment.

Step 2: Writing a Detailed Introduction to Provide Context

Explain the background of the task and why it matters. For example, if you’re documenting a procedure for “Testing Circuit Boards,” your introduction could mention that this step ensures product safety and reduces defects. Workers will understand how their role impacts the product’s quality, motivating them to follow instructions carefully.

Step 3: Outlining the Purpose of Each Task

Explain why it is important to perform the task. For instance, if the task is “Calibrating the Cutting Machine,” explain that proper calibration ensures precise cuts, which reduces waste and maintains product consistency. This knowledge helps the workers understand the significance of the particular task to production and productivity.

Step 4: Providing Step-by-Step Directions

Number the steps you will describe clearly and divide the general process into individual stages. Use simple language like,

- Insert part A into slot B.

- Start now by pressing the green start button.

Never assume that something is clear to you and that your knowledge will be clear to everyone. Each step should designate one action to avoid getting confused by too many actions at once.

For example:

Step 1: Switch on the machine, by pressing the power icon that is normally located at the main interface of the device.

Step 2: It should be correctly placed in the feeder tray to avoid developing a jam through improper alignment.

Step 5: Visualize the Manufacturing work instructions

It is good to include diagrams, photos, or videos to elaborate on the content of the steps. For instance, an illustration of the ‘feeder tray’, as described in Step 2, should be easy for the workers to locate. Diagrams that explain where each part goes can be very helpful even if the instructions are already very detailed. The use of visuals helps to minimize mistakes and the aspect of visuals is most useful to employees who are new to a company.

Step 6: Verify Accuracy with Experts

Whenever you are done with the instructions, share your document with experienced workers, engineers, or supervisors to read through. They will trace any failure and any missing link in the sequential processes or the measures that have been practiced. For instance, they may recommend safety precautions such as wearing gloves while operating certain equipment. This way the instructions given are accurate and also possible to follow.

Step 7: Use Digital Platforms for Documentation (MWI)

Instead of making work instructions on paper, centralize the work instructions on a single medium that is electronic. Manufacturing Work Instruction software is used to generate, distribute, and manage the updates and usage of these instructions, such as Document360. They are available on tablets or computers thus minimizing the chances of using old copies. For instance, if there is a change in maintenance procedures of a certain machine, change can instantly affect all the units.

Step 8: Train Your Team

Once you’ve created and shared the instructions, hold a training session. For instance, if the operation is to control a CNC machine, allow the workers to practice how they are to adhere to new instructions while under observation. It allows the practical reinforcement of each concept and makes them confident when applying the instructions in actual working scenarios. By training, the workers are also able to come up with questions during the training and have those areas that need to be clarified explained further.

The benefits that companies receive after following all these steps include improvement in efficiency, safety, and consistency hence improving on the reduction of errors that often arise from nonstandard processes.

What Are Some Platform Recommendations for Manufacturing Work Instructions?

The choice of platform can tip the balance when it comes to developing well-articulated manufacturing work instructions. Here are three platforms that I suggest; with Document360 being the most recommended.

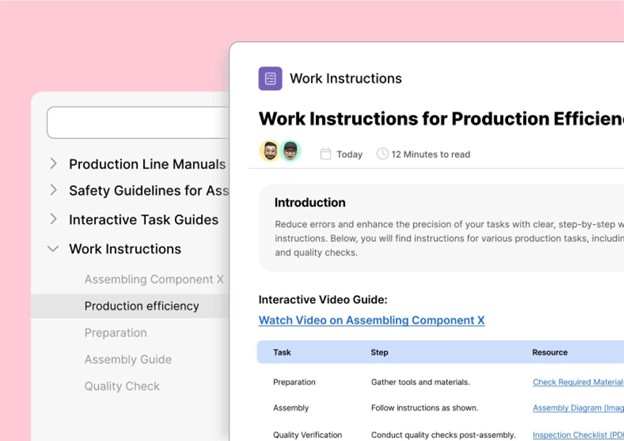

Document360

Document360 allows manufacturing work instructions to be compiled and stored in a central location. It has a highly developed function of knowledge base management, and in addition to it, features like Eddy Assistant, which allows finding the needed information as soon as possible. This helps reduce the time spent searching for instructions so that errors on the shop floor are kept to the bare minimum.

Using version control, workers can be certain they are adhering to up-to-date procedures. Some of the benefits are that engineers can easily combine efforts with quality managers and operators to develop precise and understandable instructions. They embrace multiple media as it is easy to insert images, diagrams, and videos that help explain some challenging operations.

Here the intelligent content editor also comes with suggestions and clarifying tools for the documents’ preparation. Another aspect of the platform addresses the always-increasing demand which means that every single worker is always able to find the most suitable work instruction at a moment’s notice, thus making it easier to cut out wasted time.

The whole concept of Document360 as a centralized tool changes the way manufacturing teams approach work instructions which makes it extremely useful in enhancing efficiency and production quality.

Streamline manufacturing with Document360’s knowledge base. Schedule a demo to simplify work instructions!

Book A Demo

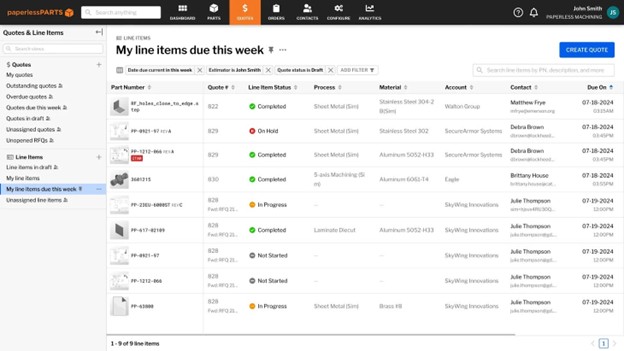

Paperless Parts

Another really good source for manufacturers interested in automation and quoting is Paperless Parts. They make work instructions creation more efficient by connecting to CAD files. One, it can amend things in real time and develop what the employees on the floor can understand in terms of charts and displays. However, it is not as diverse as Document360 when it comes to documentation.

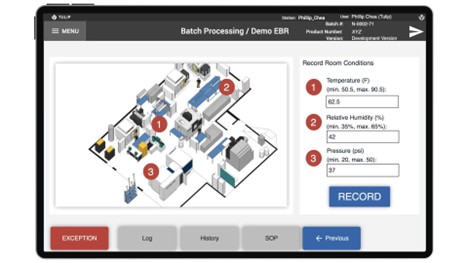

Tulip

The core of Tulip is to integrate the shop floor with analytics. It assists manufacturers in developing particular work instructions through its application development function. Tulip can also use the app-building feature to create work instructions for the manufacturers. Tulip also supports adding tools and documents in multimedia form to work instructions. However, its interface is less self-explanatory than Document360 and may take a far longer time to set up.

Note: While all of the three platforms have their strengths, Document360 is the most suitable platform for manufacturing work instruction. Due to its high usability, collaboration features, and detailed documentation, it is the best one for any organization that aims to enhance manufacturing operations.

3 Manufacturing Work Instructions Industry Examples

Below are examples of manufacturing work instructions for industries.

Automotive Manufacturing Assembly Line Work Instructions

They are very clear procedures, which outline how individual parts of an auto are put together, and how this work should be done effectively, and safely. These process instructions subdivide complicated undertakings into operant procedures, such as erecting motors, joining parts, or connecting circuit boards and electrical circuits, and are often typed or illustrated through diagrams or videos.

For instance, the case of the Toyota assembly line process leverages the Toyota Production System with the principle of ‘just in time ‘ in that only the requisite elements are made available at the right time. One of the TPS principles is thus, “Automation with people’s feelings makes a company efficient yet responsive.”

These instructions also contain important safety measures and standard inspections, so that no two cars are alike and you can be sure that the quality is kept at an optimal level. Torque specifications for bolts must be applied, regular checks and balances done, and tools used should be marked. The use of standardized work in organizations such as Ford reduces variance and therefore improves productivity.

More so, such instructions are crucial in enhancing product quality and innovativeness, particularly in the automotive manufacturing industry which has several regulatory standards to observe lest the end product causes harm or reduced performance.

Pharmaceutical Manufacturing and Compliance Procedures

They are controlled instructions that guarantee the safety and quality of produced drugs. These procedures are actually regulated by the Good Manufacturing Practices (GMP) policies which outline the measures to be taken in order to have a quality, safe, and effective product. These range from sourcing materials that make up the final product, using sterilized utensils/equipment, and even administering the right doses required by the final consumer Profile, packing, and labeling.

For instance, Pfizer has rules on compliance with the production of vaccines, among others. They describe each step of the process and the storage temperature index besides giving time frames for mixing processes to avoid contamination. The National Institute of Health has described how GMP guidelines mean that “Each process step must therefore be actionable, documented, and well-provable to provide a plausible trail of each batch’s origin.”

These procedures are important in pharma because any variation can pose a risk to the patients. They have to independently maintain cleanliness protocols, wear appropriate protective equipment, and regularly check conditions in the environment, such as humidity or air quality at a workplace. Other firms in the industries also apply strict paperwork addition, for instance, Johnson & Johnson firm also has many papers to fulfill the FDA standards to warrant their products are safe to be sold in the market

Guidebooks for Sub-Operations

Sub-Operation Instructional Procedures are special guidebooks applicable to manufacturing situations and describe specific operations within that particular setup of operations. These guidebooks contain detailed instructions on performing specific tasks in connection with certain sub-tasks that relate to the machine’s calibration, assembly of components, or testing procedures. Every task is divided into easy steps and is usually illustrated by such tools as flow charts or diagrams.

For example, sub-operation guidebooks in Intel’s semiconductor manufacturing contain detailed specific instructions involving such processes as wafer testing and or chip assembly. These include descriptions of how tight or loose the tool must be set as well as the permissible environmental conditions conducive for a particular operation, such as a clean room status. As Intel has said, “Consistency and precision are mandatory in sub-operations, and any kind of error may lead to a total batch being unleveled.”

Likewise, sub-operation guidebooks are used in GE for technical processes, such as turbine manufacture or airplane engine overhaul. Each instruction guarantees the proper workflow and performance of workers, focusing on safety regulation and tool utilization, which decreases the chances of mistakes or reverting to earlier stages. These guidebooks assist in minimizing work complexity together with the proper working mechanisms relevant to the organizations’ departments and various acts regulating business operations.

Conclusion

Are you still wondering if manufacturing work instructions are worth the effort? The answer is simple: absolutely. Clear, detailed instructions make life easier for your team, reduce mistakes, and ensure consistent product quality. They streamline training, boost productivity, and keep your operations running smoothly. With well-written work instructions, everyone knows exactly what to do and how to do it.

If you’re ready to take your manufacturing processes to the next level, use Document360. It offers an easy-to-use platform for creating, managing, and sharing work instructions. With Document360, you can ensure your team has access to the right information at the right time—helping you achieve better performance and operational efficiency. Try Document360 today and see the difference it can make!

–

–